The automation of production lines brought great benefits to companies in terms of optimizing resources, saving time and minimizing errors. However, whether an automated production line is more or less efficient will depend on the software used for organization, and how optimized the communications are with the rest of the company's IT systems.

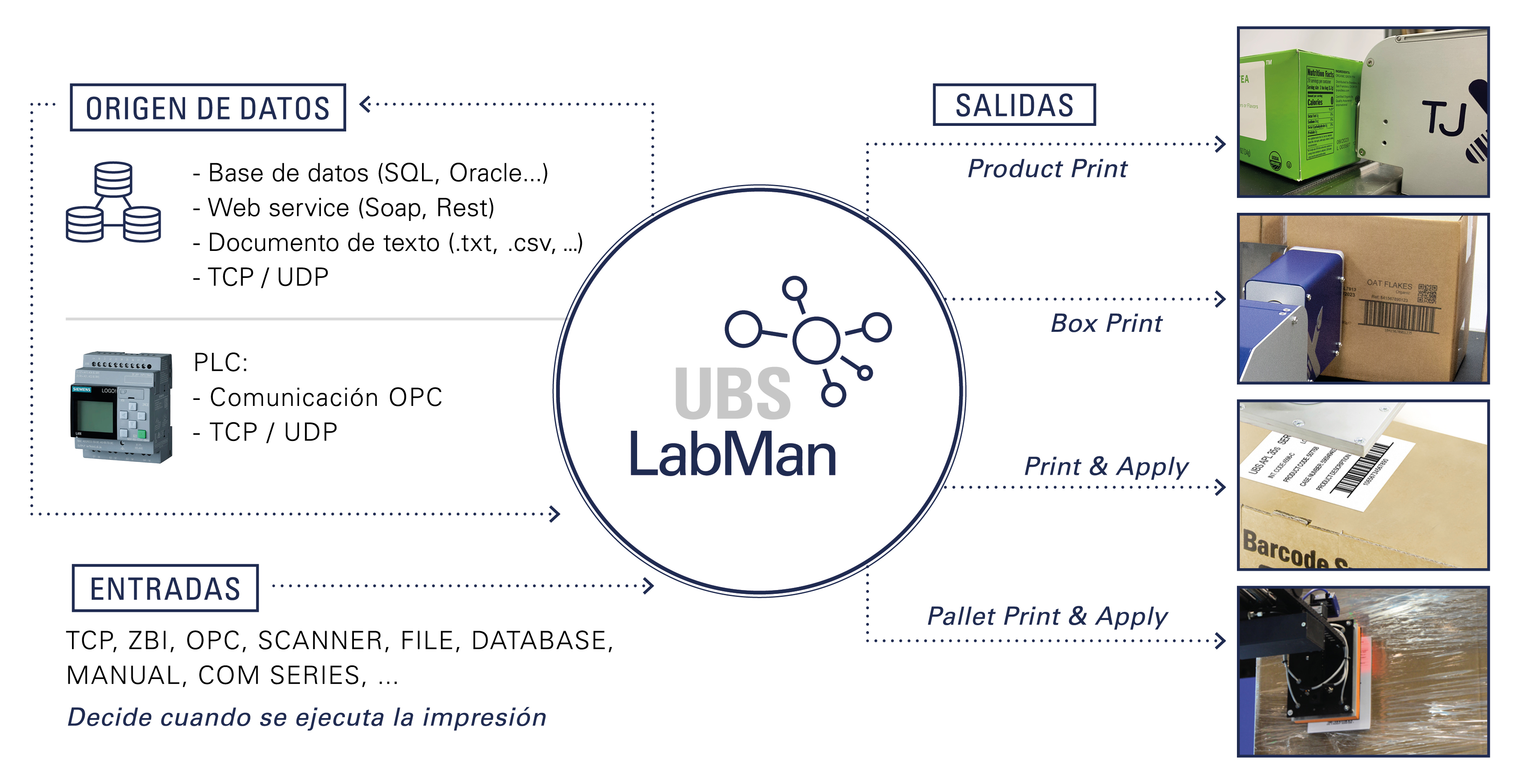

At UBS we developed our own labeling management software, UBS LabMan, which is as powerful in data processing as it is intuitive in handling, to get the most out of our labeling, coding and marking systems. The common feature of all our products is the ease of integration into any production line, even though competition in the industrial sector is increasing.

The conditions of the global market, especially with the incidence of the Covid-19 pandemic, forces organizations to get the most of software systems and complementary services providers, such as labeling, coding and marking in all the stages of the production lines.

Comprehensive management of the labeling, coding and marking system

UBS LabMan is an ideal tool thanks to its modern user interface, easy to use and powerful communication management for data processing. Developed in a web environment to facilitate access from any computer platform or device, it allows both local and remote access for management and consultation in real time of each production line, including historical and statistical data.

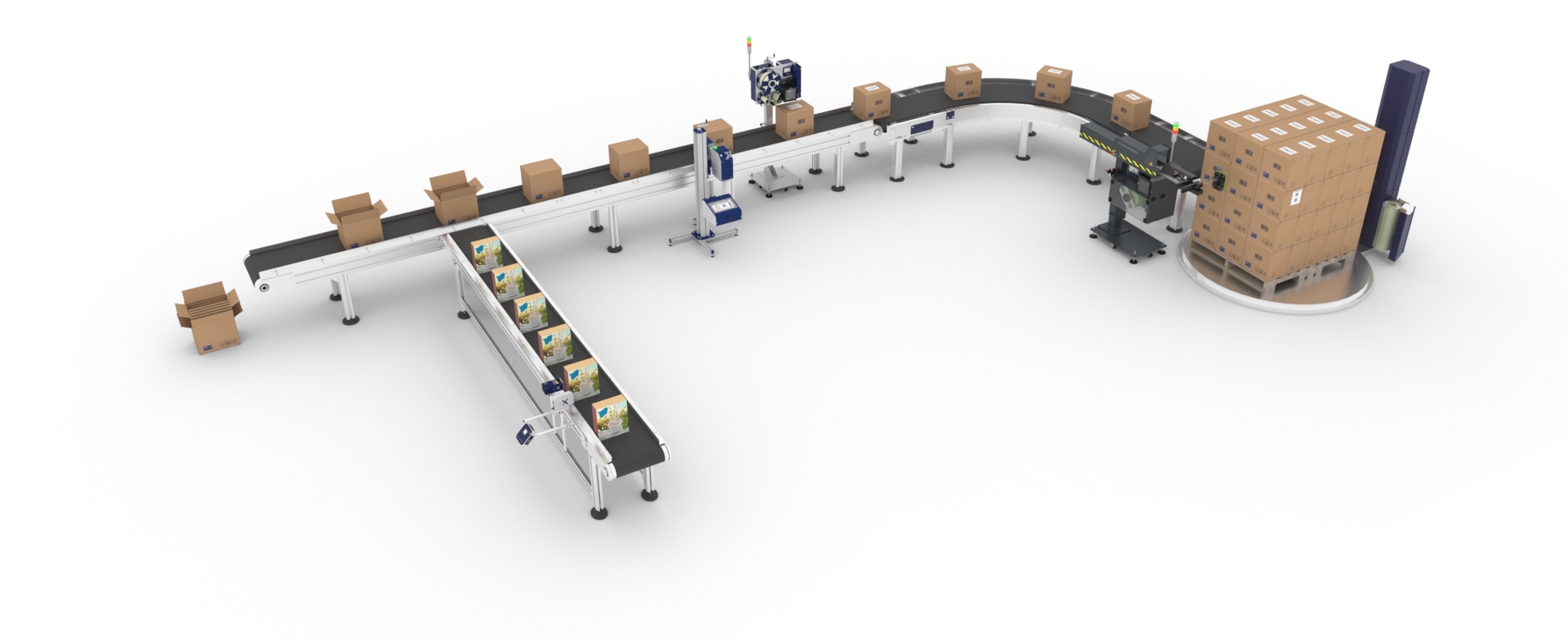

At UBS we provide a complete service of labeling, coding and marking systems, which includes everything from label design (using UBS Designer) to pallet coding; and UBS LabMan is the brain that controls all processes with maximum efficiency.

Messages created with UBS Designer are sent by UBS LabMan to the indicated printing equipment, while communicating with the company's Enterprise Resource Planning (ERP) or Manufacturing Execution System (MES) systems, as appropriate, to interact in a bidirectional way.

Our labeling management software identifies products from different lines, manages print queues and, integrates and centralizes all data with the client's ERP or MES to generate the appropriate labels for each logistics unit, with the necessary information to guarantee their correct storage, transport and traceability, in accordance with the recommendations and regulations of GS1 international.

UBS LabMan, a complete labeling management tool

Among the most notable features of UBS LabMan, there are:

-

It is accessible from any computer on the local network, reads the necessary data and transfers it to the computers registered in the application.

-

It adapts to any production line.

-

Manages data in real time and registers the labels in the client's ERP or WMS immediately.

-

Assigns equipment and printers to multiple users simultaneously, if necessary.

-

Offers label preview.

-

Monitors the labeling process and the status of the equipment.

-

Integrates easily with the customer's ERP and WMS systems.

-

It has a connection with different data sources.

-

Increases production efficiency and line effectiveness.

-

Contributes to cost savings.

-

It is flexible in relating format variables with data source fields.

-

Offers reports on the history of actions taken.

-

Can be connected to multiple external peripherals.

UBS LabMan and 4.0 industry

Talking about industry today forces us to talk about interconnectivity, automation, machine learning and real-time data. Data management is as important as the production of goods itself. It is the so-called 4.0 industry. UBS LabMan fits like a glove in a highly demanding environment in terms of efficiency and productivity. How?

-

Reduces the number of interventions and avoids human error.

-

Provides different ways of selecting tasks.

-

Enhances efficiency in the labeling process.

-

Offers maximum coding precision.

-

Simplifies the process of adding new formats.

-

Communicates easily with all kinds of smart devices.

-

Offers constant monitoring of the production line.

Adapting to the end of production line

UBS LabMan stands out for its ease of integration in any production line, also in the last step: the coding of pallets.

-

Adapts to all types of pallets: variable in height, double and triple height, peak, and semi-pallets.

-

Generates serial shipping unit codes (SSCC), known as pallet license plates, of 18 digits.

-

Offers the possibility of reprinting labels.

-

Offers three operating systems:

1. Automatic: the production line communicates with UBS LabMan to indicate the product to be printed, without human intervention.

2. Semi-automatic: the operator indicates which product will be printed on each line, and then the production line communicates with UBS LabMan to indicate when the pallet is in the labeling area.

3. Manual: the operator chooses the product and sends the label to a printer of his choice.

Do you need software for data management and administration of industrial printers?